Product description

This well service twin pump cementing unit uses on the fly mixing.

Our well services twin pump cementing equipment is custom designed and built according to our customers specifications and tailored to suit the local markets of our customers.

The twin cementer can be specified with different engines, transmissions and pumps. Additionally it can be had in different configurations such as trailer, skid or truck mounted.

Our design advantages:

- High durability components to withstand harsh operational loads and minimise failure rates.

- Ability to withstand harsh environmental conditions.

- Ease of maintenance and disassemble of components.

- Ease of operation with clearly laid out control panels and operation procedures.

Project Details

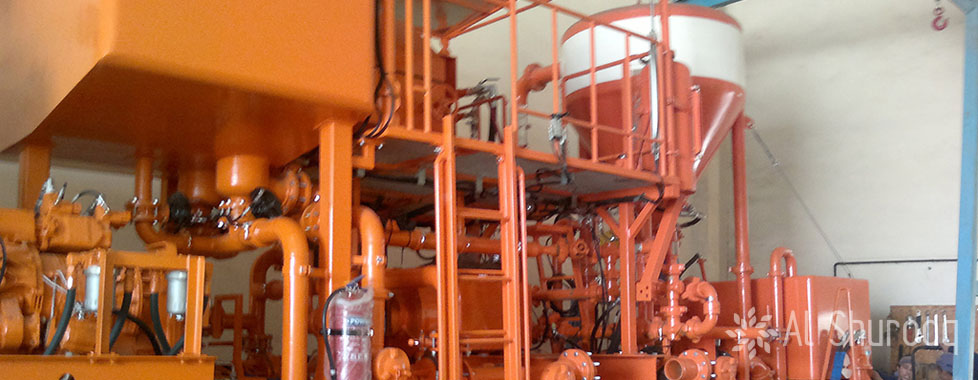

Trailer mounted twin pump cementing unit with mixing system and surge tank

- Trailer: 2 axeles, 315R 22.5Rims.

- Deck engine: 2 x Detroit Diesel series 60 // CAT C18 (575 – 630 bhp)

- Transmission:Allison 4700 OFS. // CAT CX31-P600

- Control panel data acquisition equipment with automatic density control, recording system.

- Recording system: Client specified

- Triplex pump: 2 x SPM TWS600S HD or Gardner Denver GD-compact for back to back operation, alternative brands and configurations possible.

- Centrifugal pumps: Garden Denver 6″x5″ , Double life 6″x5″.

- Fluid and air tank: hydraulic, lubrication, waste oil and air tanks

- 20BBL displacement tank

- Surge tank with mixing tank for on the fly mixing

- High and low pressure piping